News Category News Category |

|

|

|

Product Category Product Category |

|

|

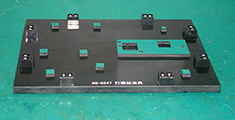

| ICT online testing instrument, mainly used to check the fault components and welding fault, in the next board welding process, there are problems of the board (such as solder against, problems such as short circuit) |

|

|

|

|

|

| Wave soldering furnace jig, for example: circuit board above which the original need protection; which is welded components; whether there is element requires high anti floating; what need righting issues. |

|

|

|

|

|

| According to the different requirements of customers, using imported synthetic stone production, and in local easy to wear and has special requirements for the position inlays titanium alloy, ensure vehicles wear durable and not easy to deformation, with long service life, improve customer the stability and effectiveness of the furnace. |

|

|

|

|

|

| The articles mainly for the flexible board (FCB), sheet, shed plate, aluminum plate, the irregular shape of plate in the red plastic printing, solder paste printing, SMT, reflow soldering process of the carrier plate, and even more in production and improve the production efficiency. |

|

|

|

|

| |

|

| |

|